At SPL, various areas of manufacturing of advanced micromaterials are investiaged. A special focus is laid on novel, porous materials suited for emitter tip densification for future high current density emitters.

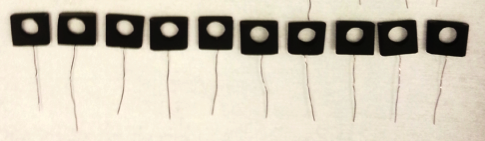

Silicon MEMS manufacturing

MEMS processes are investigated to manufacture high precision propulsion devices, providing high alignment accuracies and the ability to batch process propulsion components. This includes electrospray emitter packaging, and the extractor aperture grid.

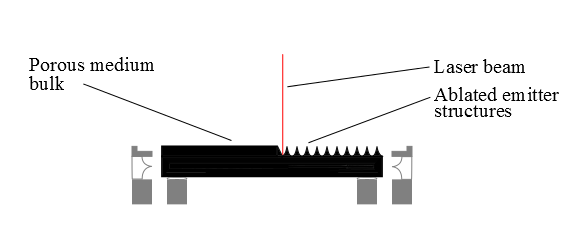

Laser ablation

Laser ablation techniques are studied and used to manufacture dense arrays of emitter structures, that can be used for electrospray propulsion.

|

Materials synthesis

Research focuses on synthesis of novel materials with defined parameters that can be optimized for specific purposes. This includes porous media optimized for porous emitters and high internal surface area electrodes.

|